DYEWORKS

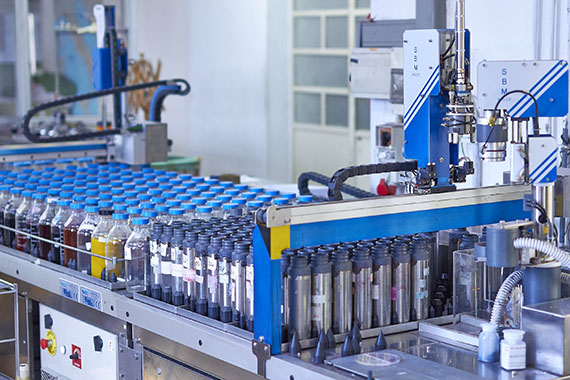

THE LABORATORY

Heart and soul of our dyeworks makes every day about 100 recipes, suggests color studies, helps in making folders, checks fiber samples and also performs quality checks before each shipment.

Thanks to the highest professionalism and the modern technologies used, the laboratory is able to ensure the accuracy and speed in color reproduction.

YARN DYEING EQUIPMENT

The dyeing process is carried out in new dyeing tanks equipped with the latest technology, in order to ensure the best results over each type and composition of yarn. In order to guarantee an accurate color reproduction and shade uniformity, we use only dyes of the best suppliers (Clariant, Dystar, Huntsman and Yorkshire) all of which are in accordance with European directives. Upon request, we do provide written statements regarding the origin of the dyes used. We also offer a wide supply of dyeing tanks for small quantities and productions.

DYEING TANKS

Despite the fact that the weight of the dyeing tanks may vary according to the type of yarn and the different needs of the customer, the following are the optimal loads:

ON EVERY YARNS

10

kg

240

kg

13,5

kg

280

kg

960

kg

25

kg

480

kg

30

kg

500

kg

60

kg

720

kg

1000

kg

120

kg

780

kg

ONLY ON CERTAIN YARNS

1,5

kg

5

kg

10

kg

6

kg

11

kg

7

kg

12

kg

8

kg

13,5

kg

9

kg

For the white & pastel shades the maximum load is 480/500 kg.

DRYING

This important step in the enhancement of the yarn, is made with a modern hot dryer that ensure uniformity in the drying process and volumizing of the yarn through the rotation and enlargement of the skeins inside the room. The particular type of ventilation, the temperatures employed, the residence time in the room and the preconditioning both in the last room and outside, allows the yarn to obtain a high volumization and an excellent final touch with due to the right degree of humidity. This type of drying is specifically suitable for knitting yarns.